In 1999, Advertising Age recognized the phrase “A Diamond is Forever” with its “Slogan of the Century” award for good reason. The slogan, create by the De Beers marketing agency in 1947, revolutionized the diamond industry by establishing the diamond as the prominent symbol of everlasting love. Today, no engagement is complete without one.

In 1999, Advertising Age recognized the phrase “A Diamond is Forever” with its “Slogan of the Century” award for good reason. The slogan, create by the De Beers marketing agency in 1947, revolutionized the diamond industry by establishing the diamond as the prominent symbol of everlasting love. Today, no engagement is complete without one.

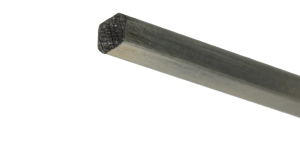

On the surface, it would appear diamond stones and diamond-shaped wire have very little in common except their names and (in some cases) their shapes. But dig a little deeper and you’ll find they have more in common than you realize.

Diamond stones are strong and durable, and so is diamond-shaped wire. Its unique shape distributes stress more evenly than other wire shapes, resulting in superior strength and durability. Like a diamond, it resists bending and deformation. This makes it particularly suitable for applications that require long term resilience.

Diamonds catch the light and are beautiful to look at. Diamond-shaped wire is also aesthetically pleasing, and its profile allows more light and air to pass through it than other wire shapes.

Where It’s Used

Our customers don’t always tell us how they use the many different shapes of wire we provide, but we know that some of them use our diamond-shaped wire to make Heli-Coil® inserts and thread repair kits, which end up in assemblies throughout multiple industries, such as automotive, aerospace, agriculture, consumer appliances, and recreational power sports (ATVs).

There are a variety of uses for diamond-shaped wire in the aerospace industry. It’s typically made of high strength alloys such as Inconel or stainless steel, which provide superior strength and durability under extreme conditions. These wires are used to produce critical components like safety nets, filtration systems, and structural reinforcements. Their unique geometry allows for superior load distribution and stress resistance, making them ideal for withstanding the intense forces encountered during flight.

Another significant advantage of diamond-shaped wire is its ability to reduce aerodynamic drag. When used in mesh or grill applications, the streamlined profile of the diamond-shaped wire reduces turbulence and air resistance. This contributes to improved fuel efficiency and overall aircraft performance, which is highly valued in aerospace applications where every bit of aerodynamic efficiency is needed.

Just like diamond jewelry, diamond-shaped wire’s combination of strength, durability, and aesthetic appeal make it a “forever” favorite over many other choices.

Contact Us to learn more about our uniquely shaped wires.