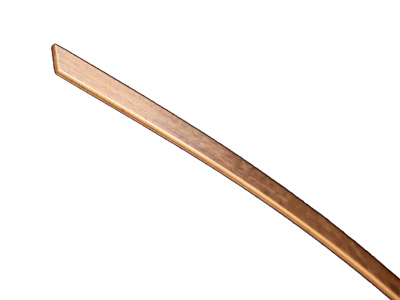

What is Flat, Copper Wire Used For? More Than You Probably Realize!

For nearly 5,000 years, copper was the only metal known to man. Today, it remains one of the most widely used metals.

Copper is an excellent conductor of electricity and heat. Precision flat copper wire is versatile, making it ideal for use in a wide variety of industries, such as:

Electronics

Flat, copper wire applications have soared in recent years due to the rising production of consumer electronics. Durable, lightweight, and compact, flat copper wire is ideal for use in smartphones, laptops, tablets, and other devices.

Automotive

Flat copper wire’s flexibility and ability to resist heat and vibrations make it an excellent choice for the automotive industry. It’s used in cars, trucks, and buses due to its unique electrical and mechanical properties. You can find flat copper wire in automotive wiring harnesses, electronic braking systems, and other vital vehicle systems.

Medical Equipment

Flat copper wire is also used in medical equipment, such as ECG machines, defibrillators, and other monitoring devices. Its slender profile allows for easy navigation. Medical professionals use flat copper wire to ensure patients are accurately monitored and fitted with lifesaving equipment.

Aerospace

The aerospace industry uses flat copper wire in multiple applications, including satellites, communication devices, radar systems, and avionics. The flat shape makes it ideal for fitting into small spaces without interference or loss of signal.

Electrical

Flat copper wire is also used in general electrical applications, like transformers and inductors. Its unique shape allows for better heat dissipation, which can lead to improved efficiency and lower energy use.

Precision flat copper wire has many advantages over other materials. It has excellent electrical conductivity, high thermal conductivity, and good corrosion resistance. It can be easily formed into different shapes and sizes to meet specific applications.

At Radcliff, we precision roll our flat copper wire from round wire. This process offers numerous advantages over the traditional slit strip product. For example, flat wire can be produced in longer continuous lengths which result in larger coil packages, eliminating welds and reducing set up time for our customers. Rolling flat wire typically has burr-free edges, which can be advantageous in applications where deburred edges are required.

Finally, a word of caution! When deciding between flat wire or slit strip (which is a metal strip slit from a wider coil), be sure to consider factors such as packaging, current capacity, material availability, width, thickness, and tolerances. Ultimately, your specific application requirements should direct your choice.

Radcliff Wire hasn’t been around as long as copper has, but we’ve learned a great deal about copper wire – and all other types of wire – since opening our doors more than six decades ago.

Contact us when you need wire expertise.

Recent News

Free Programs Facilitate Funding for Manufacturers. Are You Missing Out?

Manufacturing companies in Connecticut have access to an impressive array of free resources designed to bolster their growth and improve Read More

Beryllium Copper: Wired for Defense

You don’t need a course in metallurgy to know that the addition of beryllium is what distinguishes beryllium copper wire Read More

The Wires Inside the Electric Vehicle Evolution

In the manufacture of electric vehicles (EVs), the choice of wire materials is instrumental in ensuring efficiency, safety, and performance. Read More

Triangle Shaped Wire: Some Food for Thought

It’s by design that some of America’s favorite foods, like pizza, nachos, and ice cream cones are served in Read More