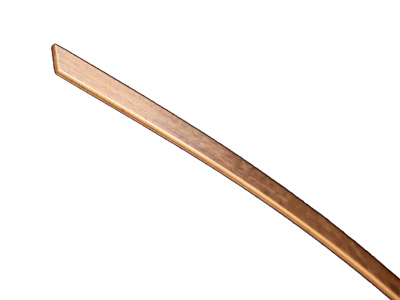

Flat Shaped Wire

Spring manufacturers have used round wire to fabricate springs since the 19th century. Today, they’re frequently choosing flat shaped wire instead. Here’s why:

Flat wire springs are more compact than springs made from round wire. They offer the same (or better) performance in a smaller package, which helps reduce the overall size and weight of the item in which they’re installed. This makes flat wire springs ideal for use in the automotive and aerospace industries, where decreased weight improves performance and fuel efficiency.

Flat wire is preferred over other wire shapes in applications other than springs due to its larger surface area, which promotes better heat dissipation and electrical connectivity.

We offer Flat Shaped Wire made from all alloys in these sizes:

- From .005” x .015” to .062” x .250”

- .093” x .187”

Note: Shapes with a 2:1 ratio (Thickness x Width) are considered rectangles at Radcliff and shapes with ratios greater than 2:1 are considered Flat wire shapes. Maximum wire width is .250”. As width is decreased, thickness may increase.

Industries Served

One of the most prominent uses of flat wire is in the electronics sector, where it serves as a key component in the manufacture of transformers, inductors, and various other electrical devices. Its ability to handle high frequency currents without significant losses makes it indispensable in modern circuit design.

In the automotive industry, flat wire has revolutionized the production of electric motors and battery packs. Its compact form and superior conductivity enable the creation of lighter and more efficient components, directly contributing to advancements in electric vehicle technology.

Plated Flat wire is also prevalent in renewable energy systems, such as solar panels and wind turbines. Its corrosion resistance and strength under extreme conditions improve the longevity and efficiency of these systems, supporting the increased adoption of sustainable energy solutions.